Faik has possessed a certain Lifecycle to manufacture the hydraulic punching tools with a unique standard that is easily complied with all of the manufacturing process and specification NO. FS_5008 as:

* Material:

All the Hydraulic Punching Tools by Faik are well known by their high quality material imported from Austria that are inspected by us. These materials are machined to produce the tooling performed by Faik that witness the birth of an Egyptian Product carrying its own Egyptian Certificate of Origin

* Machinery:

All Machinery process that is applied to the products is on CNC Machines where each product has its own program and its own line

* Specifications:

All Tooling are Heat-treated and controlled well.

We can supply all decimal sizes, not mentioned in the catalogue upon request. Special clearances can be applied for any products of any material

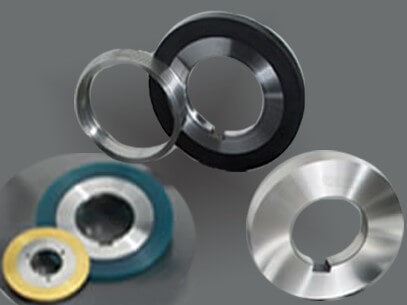

1. Hydraulic Punches & Dies

Hydraulic hole punching equipment for sheet metal, angle iron, flat steel bar, I-beams, steel tower legs, stainless steel, mild steel, brass, aluminum, and other hard materials. Punch units or kits available in hand or manual hydraulic punches, battery hydraulic punches, hydraulically powered from electric or petrol power source/pump.

A wide range of metal punch and die sizes are available for different supplier ranges, some suitable for specific metal types while others cover a range of material types. Faik punches are high quality, durable, and are from reputable industry proven manufacturers. All punches we supply we stock commonly used parts as well as providing service and repair.

Faik Hydraulic Punches and Dies are much specified and well known for their long life round about 15000 Punch for each Punch size.

Hydraulic Punches and Dies by Faik comply with a lot of sheet metal machines as:

- Ficep Machines

- Mubea Machines

- Sun Rise Machines

- Iron Worker Machines

- Kaltenbach Machines

- Pedding Hause Machines

- Kings Land Machines

- Nitto Machines

- Edwards Machines

- Durma Machines

- Geka Machines

- Shahinler Machines

- Taiwan Machines

- Metalex machines

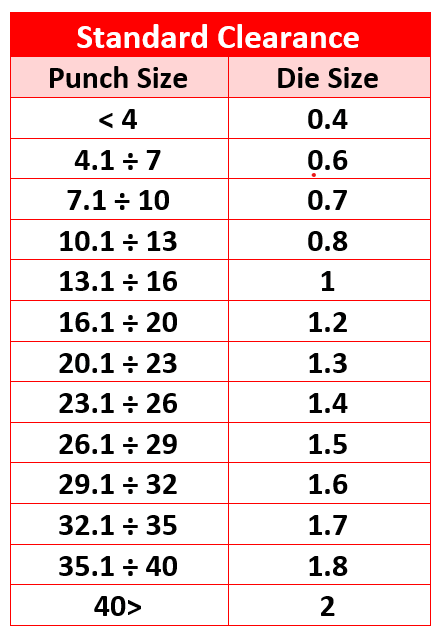

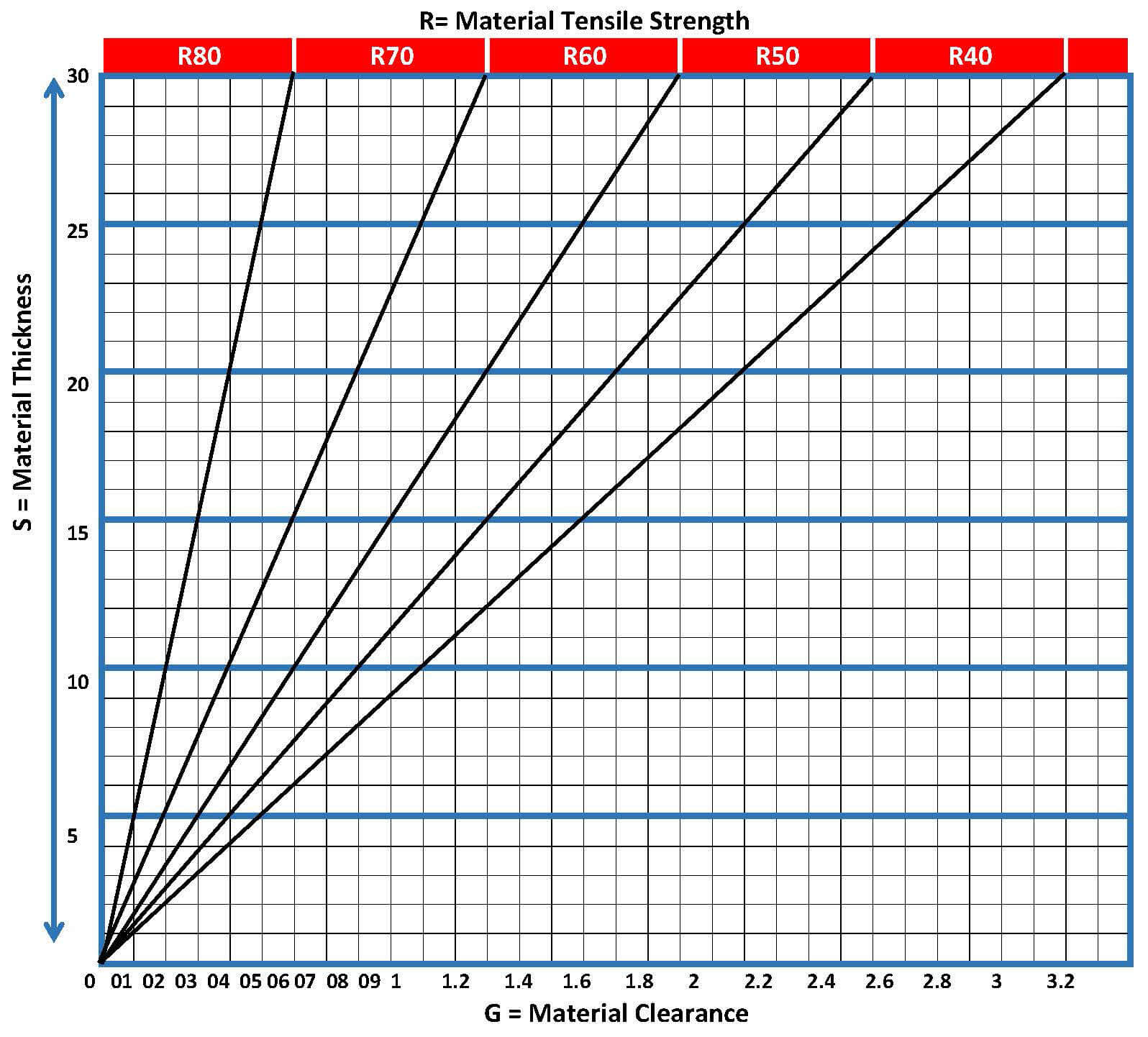

Clearance Identifications helps the user to pick up the correct die for the needed Punch. As between the punch size and the die size there must be difference due to the fraction between the punch and the die during the punching process.

2. BLADES:

- Faik uses top quality steel to manufacture our line of shear blades.

- As an aftermarket supplier, we have years of experience in providing replacement shear blades for the major ironworker manufacturers.

- Faik inventories replacement shear blades for many Ironworkers and angle-lines. They are superior to OEM brands and competitively priced.

a. Circular Blades

Circular Blades are considered as an important tooling for Faik where we have specialized in the circular blades for all kinds of machines.

3. Marking Tools:

As one of Faik missions, we found that Marking takes a huge interest of the sheet metals manufacturer. So Faik was very keen on introducing the marking products that comply with both hydraulic and eccentric machines

a. Numbers & Letters:

Marking for hydraulic machines is focused on both the profile and the type of the marking character. Faik took a special Care of the Numbers and Letters characters.

b. Identification Stamps:

The Identification stamps are simply known of 2 digits on a single punch that can be used to identify the production of a specified worker. It can be used for instance as welding stamps where we can identify the production of each welder by the stamp given upon the welded product.

Types of the welding stamps:

- 2 Circulated Digits.

- 2 Semi Circulated Digits.

- 2 Underline Digits.

- 2 Ordinary Digits

4. Special Parts For Hydraulic Machines:

Some spare parts produced by Faik are parts that originate with the machine. Where, they play an important role in the punching process or the cutting process. These spare parts are responsible for the movement of the tools used in the machines

a. Hosing:

- Hosing is responsible for managing the movement between the holders, the punches and the dies.

- They are made of special materials and they are heat-treated with special ways to compensate their needs

b. Holders:

Holders are responsible for holding the punch and help him to penetrate the sheet metal to obtain the needed hole.

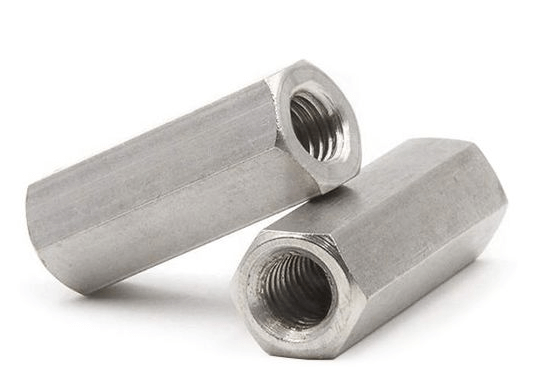

c. Holder Coupling Nut:

Coupling nuts are nuts that are used to bond the holder with the punch in order to obtain maximum stability during the punching process. Faik has manufactured a lot of coupling nuts that are computable with angle machines

d. Cutting Blade Holder:

- Cutting blade holders are holders used to hold the blades inside the machine. They are realized by high quality material imported from Austria.

- These materials are machined to produce the blades performed by Faik that witness the birth of an Egyptian Product carrying its own Egyptian Certificate of Origin.

- All Machinery process that is applied to the blades is on CNC Machines where each product has its own program and its own line.

- They are Heat-treated and controlled well. Hardening is full hardening not case hardening.

5. Machining Accessories:

a. Clamps :

b. Cassettes :

Cassettes are used in marking where marking letters are inserted inside the cassette to form the marking word needed. They are manufactured to be computable with all kinds of punching machines

Please do not hesitate to contact us for special requirements needed, where we are specialized in custom-made Tooling

We deliver As Promised.