Product Standards

In the performance of our work, FAIK uses the most advanced tools, techniques, and machinery. The plant is extensively equipped with progressive and modern machines that ensure that FAIK will remain in the highest competitive level. The Firm is equipped with more than 60 different machines enabling us to tackle the most demanding jobs that will be discussed later on.

FAIK products are specifically designed to guarantee high standards and high quality.

Faik is not limited to these products, but we would like to help in designing and manufacturing new products or new sizes to fit any application.

The products mentioned in this catalogue are available upon request.

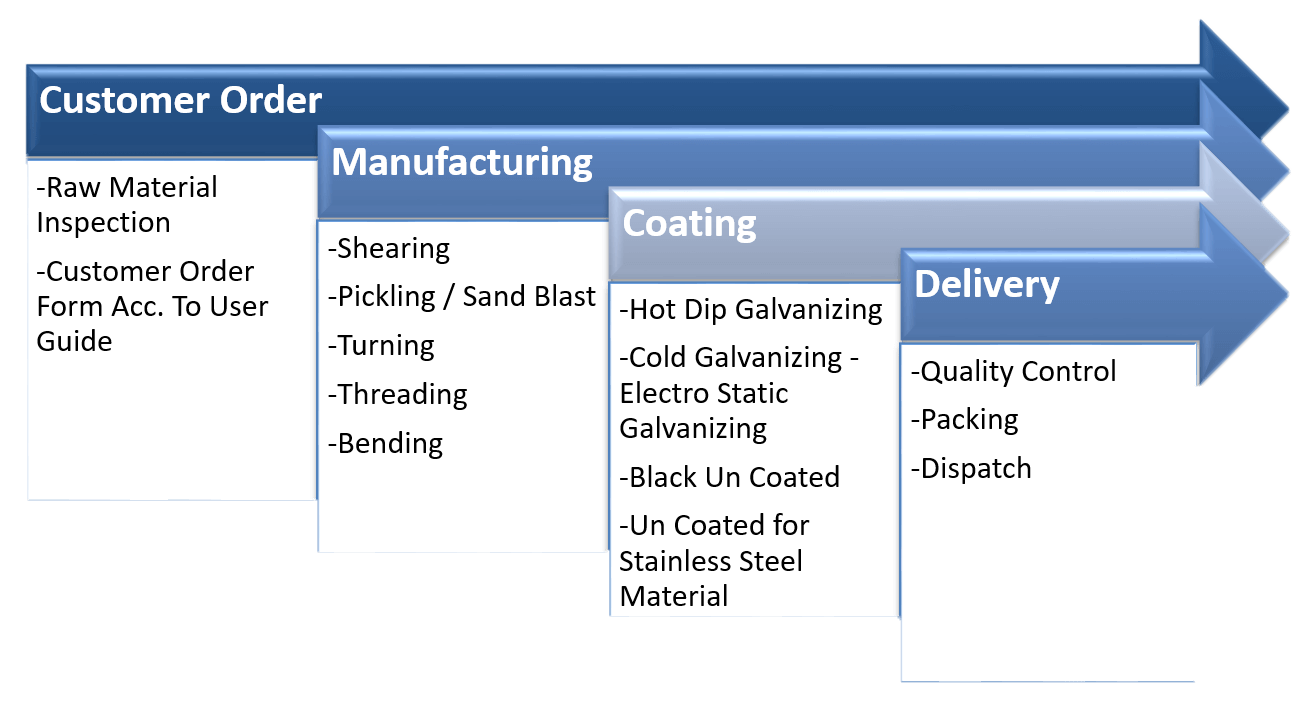

Faik has possessed a certain Lifecycle to manufacture the tools with a unique standard that is easily complied with all of the manufacturing process as:

⇒ Material

All the Anchor Bolt products by Faik are realized by high quality material imported from Austria that is inspected by us. These materials are machined to produce the products performed by Faik that witness the birth of an Egyptian Product carrying its own Egyptian Certificate of Origin.

⇒ Machinery

All Machinery process that is applied to the products is on Machines where each product has its own program and its own line.

⇒ Specifications

All products are coated (Galvanization, or Epoxy Coating) or No Coating (Black Products). This depends upon customer Request.

Please do not hesitate to contact us for special requirements needed, where we are specialized in custom-made products.

Manufacturing Procedures

Types of Fasteners:

1. Anchor bolts :

There are many types of anchor bolts, consisting of designs that are mostly proprietary to the manufacturing companies. All consist of a threaded end, to which a nut and washer can be attached for the external load. We can Manufacture from M12 up To M100 mm and From ¾ Inch to 4 Inch.

Types of Available Anchor Bolts:

- Headed Anchor Bolt Type I

- Anchor Rods Type I

- Bent Anchor Bolt – Type J

- Bent Anchor Bolt Type L

- Bent Anchor Bolt – Type Closed Eye Bolt

- Bent Anchor Bolt – Type Open Eye Bolt

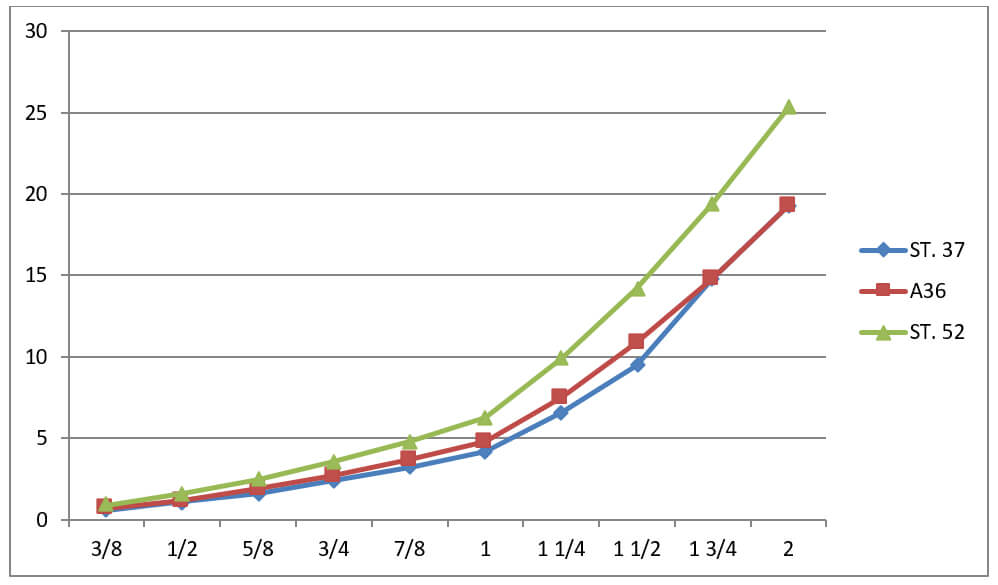

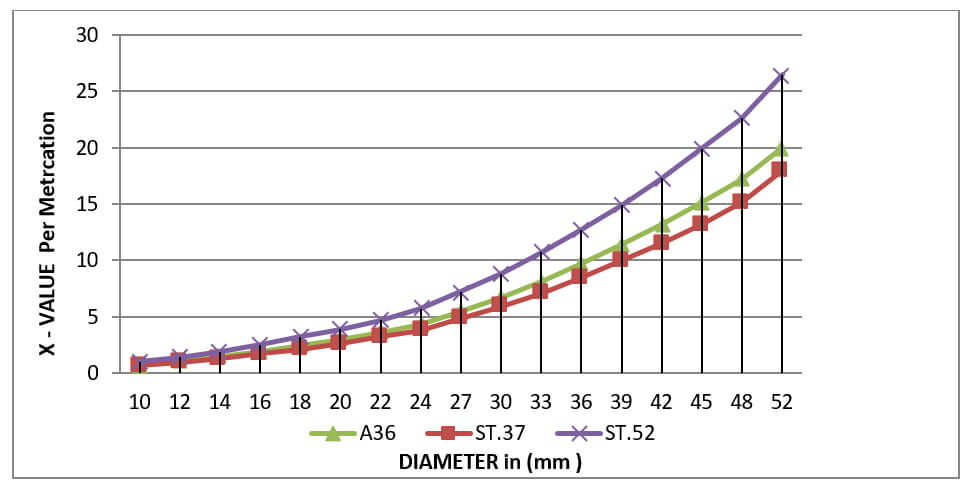

How To Choose your Anchor Bolt:

Material Strength

Diameters & Sizes Available

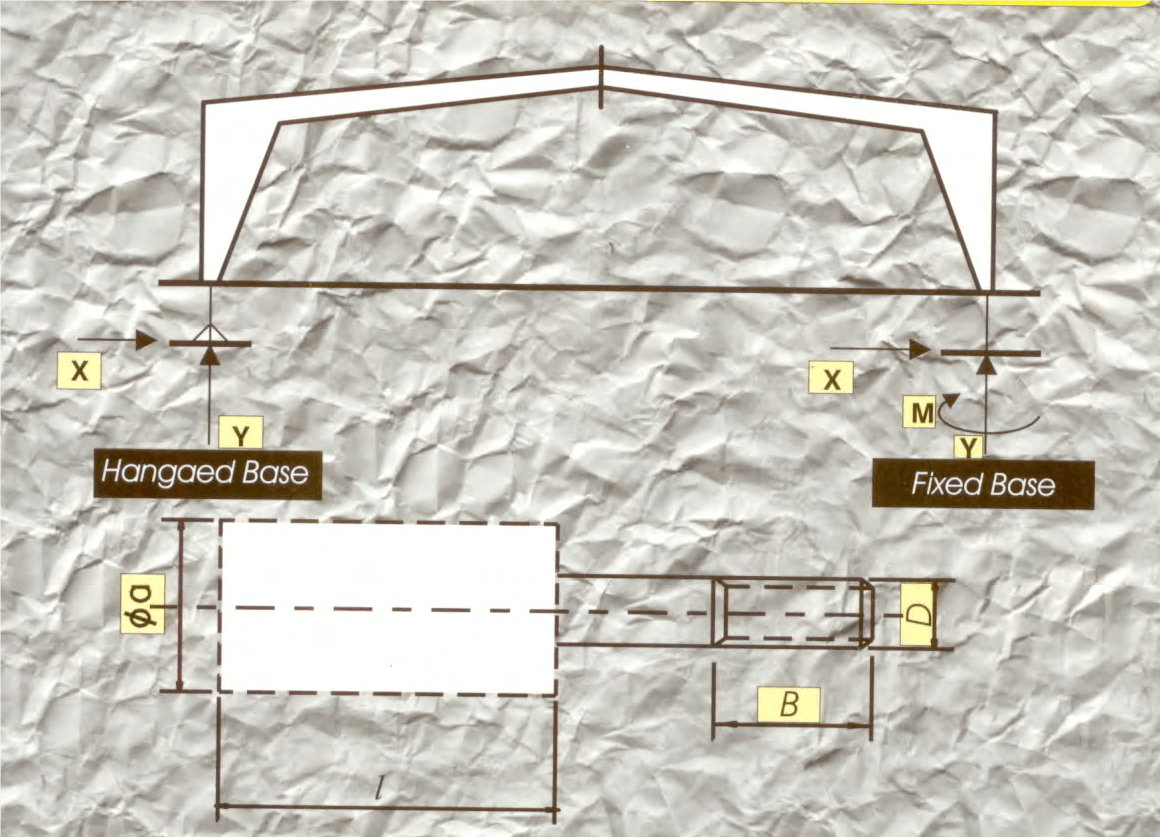

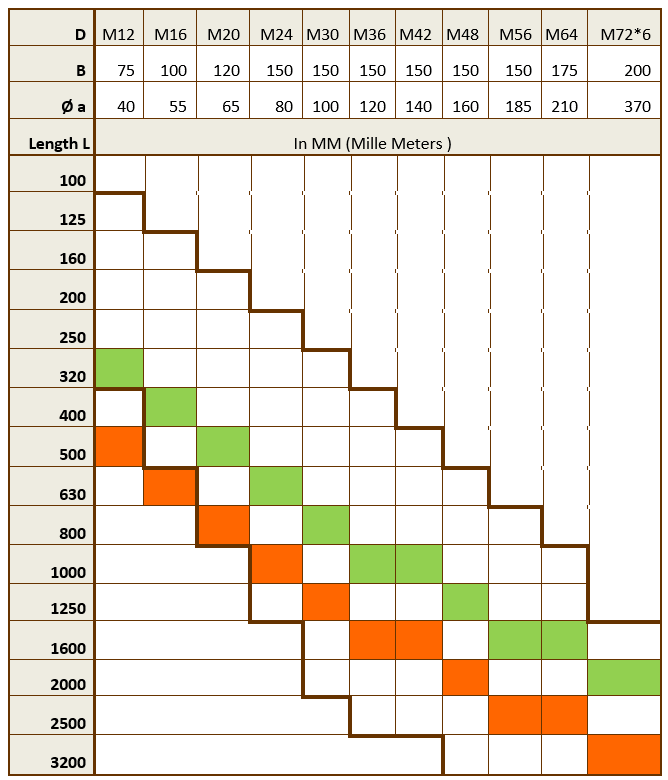

2. U Bolt:

Round U-Bolts are typically used for attaching pipe or steel round bar to a round wood or steel post. May be used to hang wrought iron pipe in mechanical installations and also be embedded in concrete as anchor bolts.

Faik can manufacture round bend U-bolts from 1/2″ through 4″ in diameter to any ASTM specification. They are provided either plain finish or hot-dip galvanized. Other metals like 304 and 316 stainless steel U-Bolts are also manufactured. All operations, including the galvanizing process, are performed in-house.

3. Tie Rods

A tie rod assembly is used to brace steel columns or heavy timber beams or used to support canopies and awnings. Tie rods are often used with clevises and/or turnbuckles.

Tie rods are commonly manufactured using low carbon steel, but higher strength assemblies can be manufactured. Carbon or alloy steel tie rod assemblies can be supplied either plain finish or hot-dip galvanized, and stainless steel tie rod assemblies are common as well.

4. Thread Bolt – Stud Bolts

All thread rod, commonly referred to as fully threaded rod and is used for general purpose fastening for anything from an anchor bolt to a through bolt. A variety of grades and materials are available.

All thread rod includes chemical and physical test reports.

All thread that is cut to length is chamfered, stamped or color coded for grade identification when necessary, and galvanized when necessary. Stainless steel are readily available and can be provided.

Thread Bolts are manufactured according to the following Standards:

- ASTM A307 Grade A

- ASTM A307 Grade B

- ASTM A193 Grade B7

- F1554 Grade 36

- F1554 Grade 55

- F1554 Grade 105

- ASTM A572 Grade 50

- ASTM A449

- ASTM A354 Brade BC

- ASTM A354 Grade BD

5. Threaded Rebar

Threaded rebar is used as an alternative anchoring method when securing sign structures, wind towers, structural steel, and other foundation applications. It is also referred to as jumbo rebar. To ensure proper thread fit the rebar must turned down to remove the deformations. This uniform surface is used to create the required threads. Plain finish and hot-dip galvanized threaded rebar anchor bolts are available.

Threaded Re bars are manufactured according to the following Specification:

- ASTM A615 Gr 75 Rebar

- ASTM A615 Gr 60

- ASTM A706

6. Bolts in Different Shapes

1- Hex Bolts

Hex bolts (six sided heads) are the industry standard for fasteners with forged heads. ASTM A307 grade A bolts, all SAE hex bolts, and several other common specifications require a standard (finished) hex head. For specifications such as A307 grade B, A325 and A490 that require a heavy hex pattern, refer to dimensional tolerances for heavy hex bolts or structural bolts.

Standard Thread Length

Bolt lengths ≤ 6″: Thread length = (2 X diameter) + 1/4″

Bolt lengths > 6″: Thread length = (2 X diameter) + 1/2″

Note: Most stock hex bolts 10″ and longer will have 6″ of thread.

Specification:

- ASTM A307A

- ASTM F1554

- ASTM A449

- ASTM A354

- ASTM F593 or any Required specification needed.

2- Heavy Hex Bolts

Several ASTM specifications require a hex head that is larger than a standard (finished) hex head. These specifications include: A193, A320 and A307B. Although A325 and A490 bolts also require a heavy hex head.

Standard Thread Lengths

Bolt lengths ≤ 6″: Thread length = (2 X diameter) + 1/4″

Bolt lengths > 6″: Thread length = (2 X diameter) + 1/2″

3- Washer Head Bolt

Forged washer head bolts are used in the pole line industry and provide increased bearing surface on the cross arm due to the integrated washer that is forged under the square head. They are commonly used with square nuts and are hot-dip galvanized to prevent corrosion. Standard thread lengths for pole line fasteners, which are longer than standard bolts, are applied to washer head bolts. A semi-cone point is added to the threaded end to facilitate easy installation.

Faik manufactures washer head bolts from 1/2″ diameter through 7/8″ diameter. These bolts are manufactured to ASTM specification A307 grade A. They are forged with a square head and large washer surface under the head.

4- Counter Sunk Bolt

Countersunk bolts are used when a smooth surface is required. Common applications include: bridge decking, walkways, and railing.

Faik manufactures countersunk bolts from 1/2″ diameter through 1-1/2″ diameter in most ASTM specifications including, A307 Grade A, A449, and Grade 8. Countersunk bolts have a head angle of approximately 80 degrees. Bolts are available with and without a slot in the head. Special tooling can be created to produce nonstandard head dimensions or bolt heads with your company’s name and/or logo.

Standard Thread Length

Bolt lengths ≤ 6″: Thread length = (2 X diameter) + 1/4″

Bolt lengths > 6″: Thread length = (2 X diameter) + 1/2″

7. Nuts

1- Heavy hex nuts:

Heavy hex nuts are slightly larger and thicker than hex nuts. There are numerous grades and the heavy pattern is typically used for large diameter and high strength bolts. Since hot-dip galvanizing typically adds 2.2 to 5 mils of thickness to the threaded portion of a fastener, galvanized heavy hex nuts are tapped oversize to compensate for the corrosion resistant coating on the bolts. They are available in ASTM A563 ( Grade A.C. DH) and ASTM A194 Grade 2H

2- Hex Nuts

Hex nuts are available in ASTM A563-A and compatible with low carbon steel bolts such as ASTM A307, ASTM F1554 grade 36, and nuts are also available in a Black. Since hot-dip galvanizing typically adds 2.2 to 5 mils of thickness to the threaded portion of a fastener, galvanized hex nuts are tapped oversize to compensate for the corrosion resistant coating on the bolts

3- Hex Jam Nuts

Hex jam nuts are thinner than a standard hex nut but have the same dimension across the flats and corners. Hex jam nuts have two common applications. A jam nut can be threaded onto a bolt and run tight against the standard nut which will lock the nut in place and prevent it from backing off. Jam nuts are sometimes used for leveling purposes

4- Heavy Hex Jam Nuts:

Heavy hex jam nuts are thinner than a standard heavy hex nut but have the same dimension across the flats and corners. Heavy Hex Jam Nuts are manufactured by Faik according to specification ASTM A563, ASTM A194, ASTM F594. Heavy hex jam nuts have two common applications. A heavy hex jam nut can be threaded onto a bolt and run tight against the standard heavy hex nut which will lock the nut in place and prevent it from backing off. Heavy hex jam nuts are sometimes used for leveling purposes as well

5- Square Nuts:

Square nuts and hex square nuts have four equal sides. These nuts have a flat bottom side and a chamfered top-side and can be used in a channel or welded in place. Square nuts are used in conjunction with square bolts or are commonly used with pole line hardware.

6- Lock Nuts:

Lock nuts are available in numerous styles, grades and finishes. The term “lock nut” is not meant to imply that there is an indefinite permanency of fixity once used. Most locknuts can be removed and some can even be reused if removed correctly. Lock nuts are most commonly available in ASTM A563 Grades A and DH and ASTM A194 Grade 2H. They are manufactured with a standard hex or a heavy hex pattern

7- Hex Coupling Nuts:

Hex couplers are used to connect two pieces of threaded material. Hex and heavy hex couplers are threaded right hand. If a right hand-left hand coupler is needed, consider using a sleeve nut.

8- Sleeve Nuts:

Sleeve nuts are similar to coupling nuts in that they are designed to connect two like-diameter fasteners. They are often used in place of turnbuckles and in combination with high strength tie rods. These custom nuts are typically tapped with right hand (RH) threaded on one end and left hand (LH) threads on the other end. This allows for slight adjustments and proper tensioning once assembled. They can also be ordered with right hand threads on each end. Sleeve nuts differ from coupling nuts because they are longer, tapered from the middle towards the ends, typically left hand/right hand, and there is a stop in the middle. Sleeve Nuts are manufactured in accordance to ASTM A563 – ASTM A194 or ASTM F594.

8. Washer:

A washer is a thin plate (typically disk-shaped) with a hole (typically in the middle) that is normally used to distribute the load of a threaded fastener, such as a screw or nut. Other uses are as a spacer, spring, wear pad, preload indicating device, locking device, and to reduce vibration (rubber washer). Washers often have an outer diameter (OD) about twice their inner diameter (ID), but this can vary quite widely.

Washers are usually metal or plastic. High-quality bolted joints require hardened steel washers to prevent the loss of pre-load due to Brine ling after the torque is applied.

Washers are manufactured by Faik in accordance to ASTM A36, ASTM A572 Grade 50, ASTM F436 Specification.

Rubber or fiber gaskets used in taps (or faucets, or valves) to stop the flow of water are sometimes referred to colloquially as washers; but, while they may look similar, washers and gaskets are usually designed for different functions and made differently.

Washers are also important for preventing galvanic corrosion, particularly by insulating steel screws from aluminum surfaces.

Types of available washers:

- Standard Flat Washers

- Hardened Flat Washers

- Lock Washers

- Round Plate Washers

- Square Plate Washers

- Tapered Washers